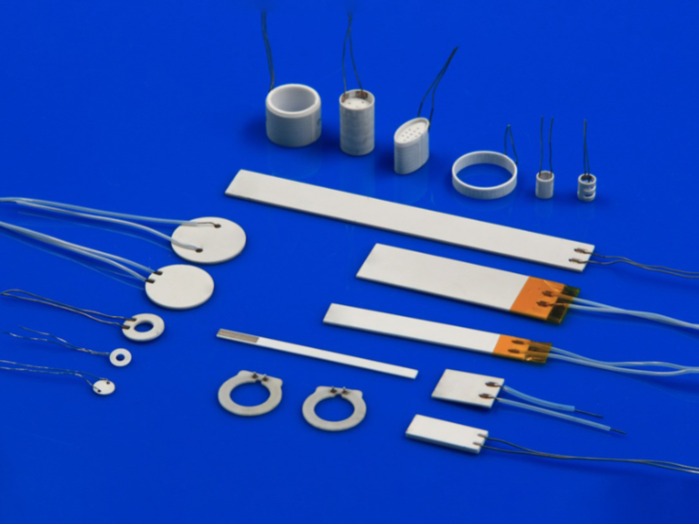

Alumina ceramic heater is a kind of high efficiency heat division uniform heater, excellent thermal conductivity of metal alloy, to ensure that the hot surface temperature uniform, eliminate the hot and cold points of the equipment. Alumina ceramic heater is divided into two kinds, respectively PTC ceramic heating body and MCH ceramic heating body. The materials used in these two products are completely different, but the finished products are similar to ceramics, so they are collectively referred to as “ceramic heating elements”.Due to the increasingly high operating temperature requirements in modern industry, ceramic heaters can adapt to, especially chemical fiber, engineering plastics, plastic machinery, electronics, medicine, food and various pipeline heating;